More businesses and energy companies are turning to wind power and renewable energy. You may have seen tall windmills in business parking lots or massed in flat fields where they can capture the constant gusts that cross the land.

The machines that generate electricity from wind are complex and require attentive maintenance. Learn about the anatomy of a wind turbine, including some key components and functions.

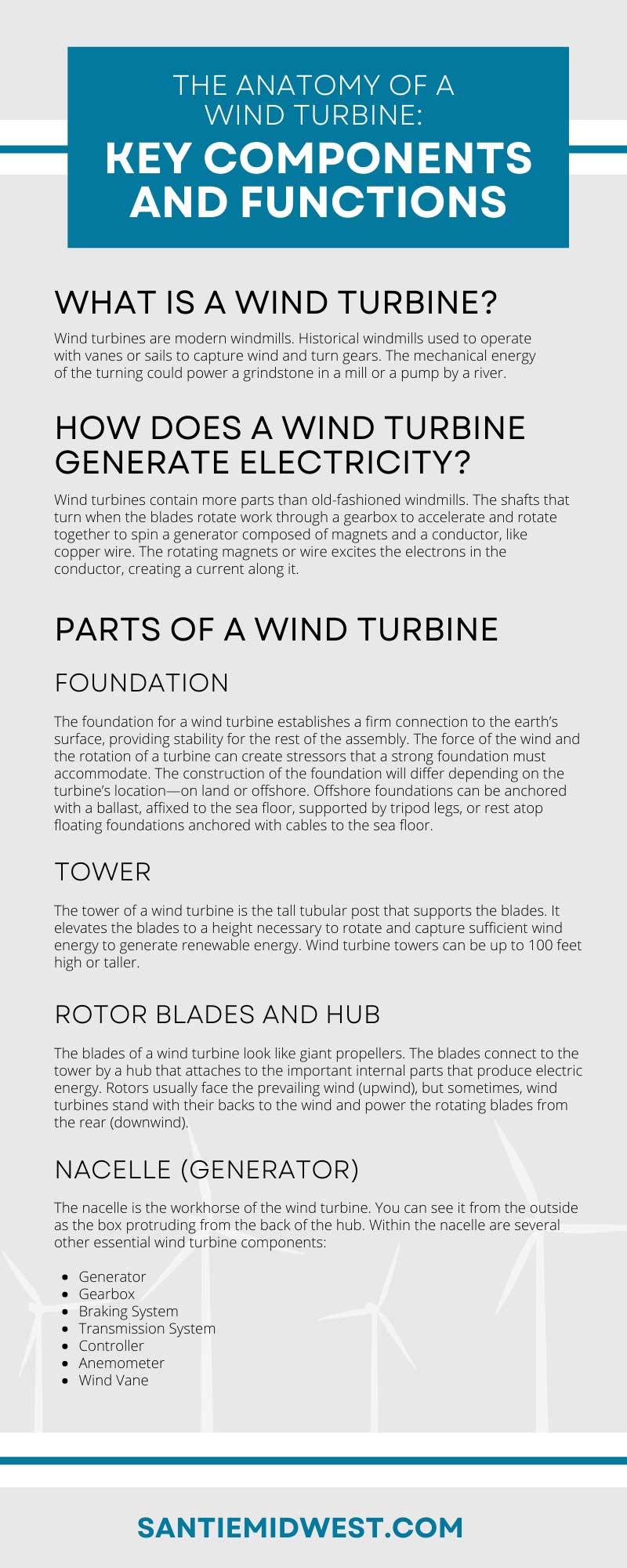

What Is a Wind Turbine?

Wind turbines are modern windmills. Historical windmills used to operate with vanes or sails to capture wind and turn gears. The mechanical energy of the turning could power a grindstone in a mill or a pump by a river.

Wind turbines, on the other hand, generate electrical energy from the mechanical energy of aerodynamic blades rotating in the wind. Turbines are significantly taller than traditional windmills to capture more powerful and constant winds.

How Does a Wind Turbine Generate Electricity?

Wind turbines contain more parts than old-fashioned windmills. The shafts that turn when the blades rotate work through a gearbox to accelerate and rotate together to spin a generator composed of magnets and a conductor, like copper wire. The rotating magnets or wire excites the electrons in the conductor, creating a current along it.

A scientist named Michael Faraday discovered induction generation of electricity in 1831; around the same time, an American physicist named John Henry made a similar discovery. Together, Faraday and Henry are considered the founders of the study and use of electromagnetism.

Parts of a Wind Turbine

Wind turbines are complex machines composed of many parts. Depending on their manufacturer, the parts may fit or work together differently. Still, the general anatomy of a wind turbine, its components, and function are essentially the same.

Foundation

The foundation for a wind turbine establishes a firm connection to the earth’s surface, providing stability for the rest of the assembly. The force of the wind and the rotation of a turbine can create stressors that a strong foundation must accommodate. The construction of the foundation will differ depending on the turbine’s location—on land or offshore. Offshore foundations can be anchored with a ballast, affixed to the sea floor, supported by tripod legs, or rest atop floating foundations anchored with cables to the sea floor.

Tower

The tower of a wind turbine is the tall tubular post that supports the blades. It elevates the blades to a height necessary to rotate and capture sufficient wind energy to generate renewable energy. Wind turbine towers can be up to 100 feet high or taller.

Rotor Blades and Hub

The blades of a wind turbine look like giant propellers. The blades connect to the tower by a hub that attaches to the important internal parts that produce electric energy. Rotors usually face the prevailing wind (upwind), but sometimes, wind turbines stand with their backs to the wind and power the rotating blades from the rear (downwind).

Nacelle (Generator)

The nacelle is the workhorse of the wind turbine. You can see it from the outside as the box protruding from the back of the hub. Within the nacelle are several other essential wind turbine components:

Generator

This is the assembly of magnets and conducting wire wrapped around a core that the mechanical energy of the wind turbine rotates to create an electric current.

Gearbox

The gearbox performs the essential task of accelerating the rotational speed the blades produce to a level that will generate electricity when the magnets or conductor within the generator spin.

Braking System

Both aerodynamic and mechanical braking systems reside within the nacelle. They ensure the rotors don’t spin too fast, which could happen in severe weather or other emergency situations. Mechanical braking systems typically stop the rotation of the blades entirely in case of service or repair. Aerodynamic braking refers to the shape of the blades themselves, twisted to reduce the maximum speed they can achieve when wind causes them to rotate.

Transmission System

The transmission system sends the electrical current from the generator to the grid, or through a transformer that modifies the current to enable it to travel long distances through electric wires. Additional transformers closer the homes that will use turbine energy will again transform the energy to voltages appropriate for the current’s destination.

Controller

This component of a wind turbine controls the pitch and yaw of the rotor blades, adjusting to gain the optimal level of power from the wind.

Anemometer

This small device collects wind speed data, which is crucial to the controller.

Wind Vane

Usually close to the anemometer, this instrument detects wind direction, making it another important data point for the controller.

Maintenance

As you might imagine, the complexity of wind turbines, generators, gears, and moving parts requires careful maintenance. Around two or three times a year, a maintenance crew will stop the turbine and take it offline to check all its components.

The computerized controller within the nacelle gets a checkup to ensure it is gathering and responding to data appropriately. All other electronic components get inspected and repaired if necessary.

A turbine’s tower and foundation may have corroded, requiring significant repairs. Bearings, gears, hydraulic systems, shafts, and sensors require inspections to ensure proper operation. Thanks to certain protection systems, a turbine’s blades can sustain damage from lightning strikes.

Wind turbine components require lubrication. The different parts may require grease or wind turbine oil, and filters will require replacement from time to time.

Wind turbine inspections, maintenance, and repairs are a complex business. Professionals who service energy companies or businesses that use wind turbines to generate their own energy can define appropriate maintenance schedules and provide complex repairs. These include replenishing lubricants, replacing parts, and repairing rotors.

Professionals rely on Santie Oil to supply the wind turbine lubricants necessary to keep these huge, complicated machines running at optimal performance. As more energy generating companies, businesses, and institutions adopt wind turbines to supply or supplement their electricity needs, Santie Oil stands ready to supply the necessary oils and greases to keep the machines running effectively.