Product Description

Overview

- High-quality polyalphaolefin (synthesized hydrocarbon) base fluids with technologically advanced additives to provide effective and efficient compressor performance.

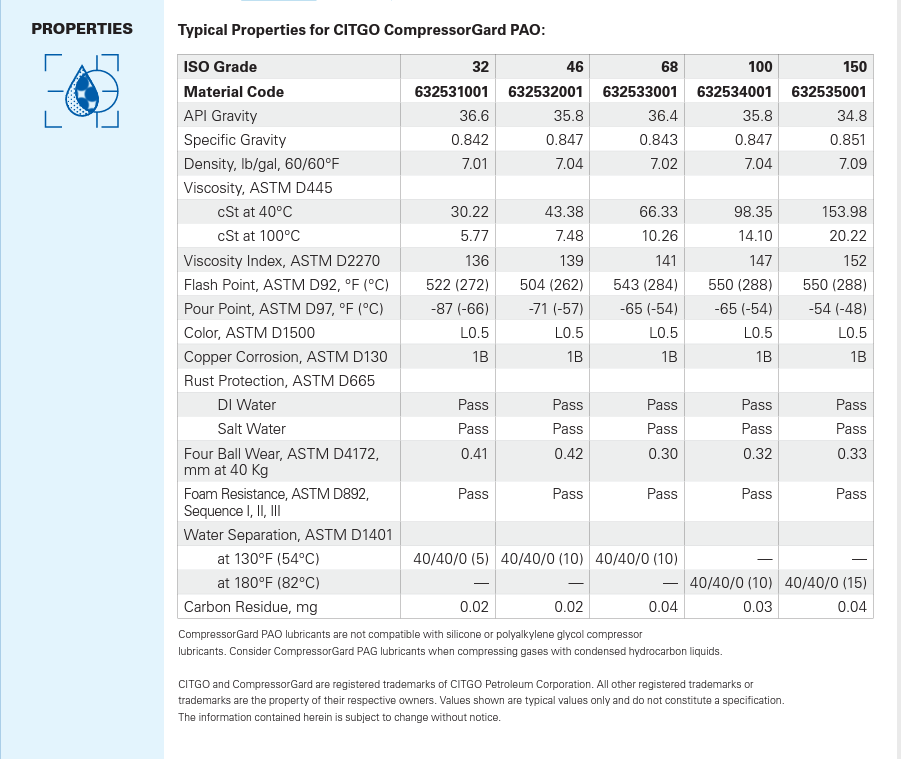

- Available in ISO grades 32, 46, 68, 100, and 150.

Features & Benefits

- Reduced danger of compressor fire and explosions that result from deposit formation.

- Outstanding oxidation and thermal stability.

- Exceptionally low pour point.

- Low varnish-forming tendencies.

- Wide operating temperature range.

- High viscosity index.

- Excellent anti-wear properties.

- Extended service life.

- Lower maintenance costs.

- Excellent rust protection.

- Fully compatible with elastomers, paints, seals, and petroleum oil.

- Low toxicity.

- Excellent Demulsibility

Applications

- Designed for use with rotary vane, rotary screw, and centrifugal compressors.

- In rotary vane and rotary screw compressors, ideal to guard against sludge and varnish deposit formation and accumulation that occurs when oil is injected directly into the high-temperature airstream. The cleaner compressor interior results in reduced component wear and increased safety and efficiency.

- In centrifugal (dynamic) compressors, the proven additive package and low vapor-forming tendencies ensure excellent performance over an extended drain interval, as compared to petroleum oil. Often remotely located and mated with integral gear sets, centrifugal compressors require a lubricant with good load-carrying ability and low foaming tendencies.