Product Description

Overview

• Designed for high-pressure reciprocating compressors operating with natural gas, carbon dioxide, hydrogen, helium, nitrogen, ammonia, and other polar gasses.

Features & Benefits

- Resistance to hydrocarbon dilution and absorption of the gas stream prevents condensed hydrocarbon liquids in the cylinder area from washing the lubricant from the cylinder walls. Other lubricants which absorb these liquids lose viscosity, which can result in severe mechanical damage.

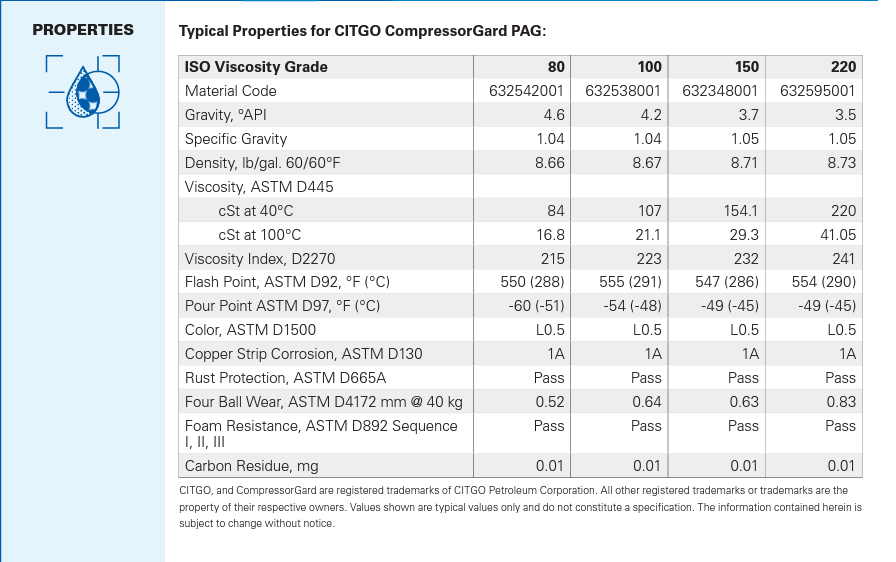

- High viscosity index and low pour points allow usage over a wide temperature range.

- Permit reduced maintenance costs and decreased downtime due to improved lubrication.

- Minimize problems in separators, meters, filters, and other downstream components due to lower lubricant consumption.

- Allow easier handling and lower disposal costs.

- Reduce absorption of lubricating oil into the gas at higher pressures.

- Minimize viscosity degradation when saturated with high-pressure gas.

- Provide excellent resistance to wash-off by liquid hydrocarbon gases.

- Offer compatibility with well bore fluids and treating chemicals, thereby reducing well impairment incidents.

Applications

- Recommended for flooded rotary screw and vane compressors used for compressing natural gas, carbon dioxide, and other gaseous hydrocarbons.

- When proper viscosity grade is selected, suitable for use as a reciprocating compressor cylinder lubricant when processing natural gas, carbon dioxide and other gases requiring chemical resistance.

- Refer to equipment owner’s manual for proper lubricant recommendation.