Aerospace engineering and aviation maintenance both require meticulous attention to detail. At the heart of this lies a vital yet often underappreciated component: aviation grease. It’s not a stretch to say that the entire aerospace industry would remain grounded without this additive. However, there’s more to this lubricant than meets the eye. To help you better understand the industry and how it operates, we’ll dissect the different types of aviation grease, their intended uses, and why they’re critical to aircraft safety and performance.

The Significance of Aviation Grease in Aircraft Maintenance

Composed of numerous mechanical systems working in synchrony at extraordinary altitudes and speeds, aircraft are marvels of modern engineering. Such systems demand high-performance lubrication to reduce friction, protect against wear, and operate reliably at various temperatures and in various environmental conditions. Manufacturers specially formulate aircraft greases to meet these stringent requirements, ensuring the durability and safety of aircraft throughout their operational lifetimes.

Types of Aviation Grease

The industry requires a diverse range of aviation grease formulations to deal with the rigorous conditions that aircraft face during operation. For example, greases used in the high-temperature environment that engine bearings deal with differ significantly from greases applied to colder, pressure-sensitive areas such as landing gear.

Here are a few of the most common types of aviation greases:

1. General-Purpose Grease

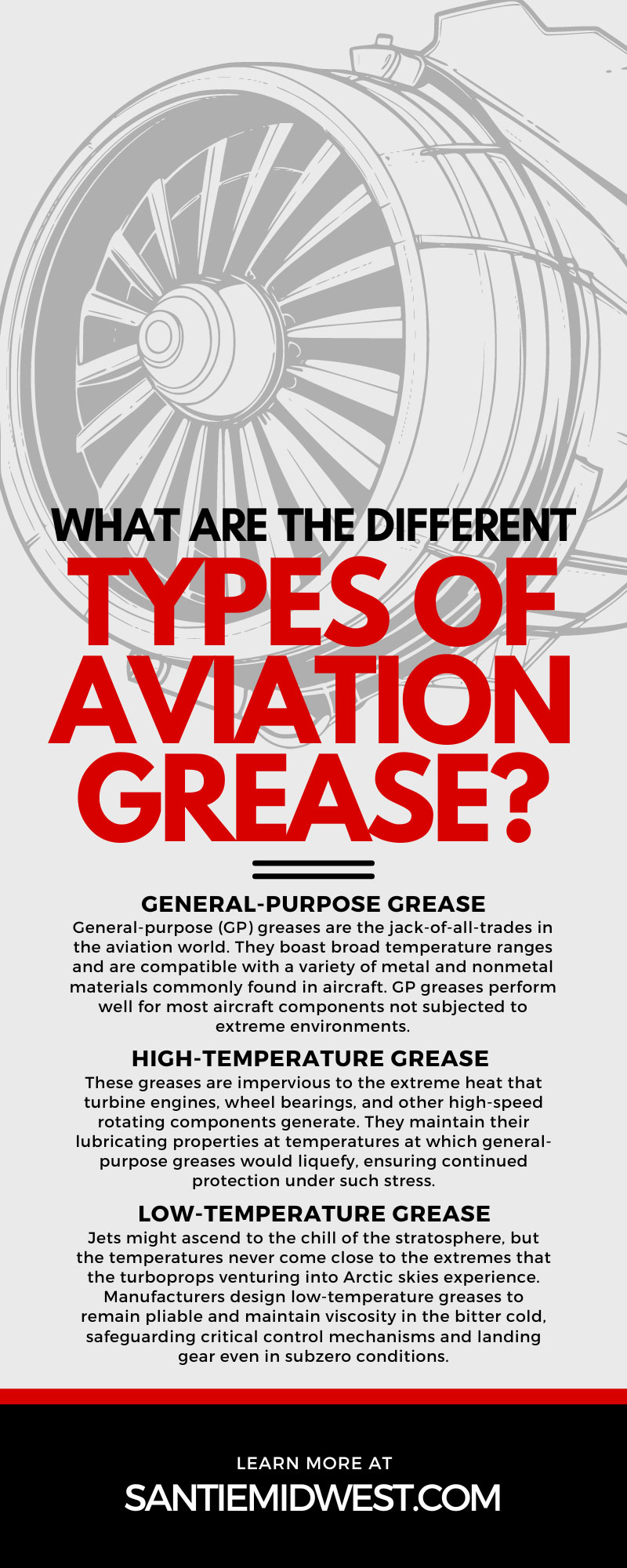

General-purpose (GP) greases are the jack-of-all-trades in the aviation world. They boast broad temperature ranges and are compatible with a variety of metal and nonmetal materials commonly found in aircraft. GP greases perform well for most aircraft components not subjected to extreme environments.

2. High-Temperature Grease

Imagine the engine compartment of an aircraft, and you’ll realize why high-temperature greases are indispensable. These greases are impervious to the extreme heat that turbine engines, wheel bearings, and other high-speed rotating components generate. They maintain their lubricating properties at temperatures at which general-purpose greases would liquefy, ensuring continued protection under such stress.

3. Low-Temperature Grease

Jets might ascend to the chill of the stratosphere, but the temperatures never come close to the extremes that the turboprops venturing into Arctic skies experience. Manufacturers design low-temperature greases to remain pliable and maintain viscosity in the bitter cold, safeguarding critical control mechanisms and landing gear even in subzero conditions.

4. Anticorrosion Grease

Aviation can be hard on metals due to the moisture and hydrosulfide gases present at high altitudes. Anticorrosion greases are fortified with inhibitors that protect against atmospheric corrosion, offering an added layer of defense for at-risk aircraft components.

5. Synthetic Grease

Synthetic greases’ claim to fame is their ability to work uniformly across a spectrum of conditions, from subzero temperatures to scalding engine bays. They achieve this thanks to their carefully engineered molecular structures, which are free from the impurities often found in their mineral-based counterparts. What they lack in specific heat resistance or cold-weather performance, they more than make up for in versatility.

Specialized greases are necessary for compatibility between various materials used in aircraft construction, such as aluminum, steel, and composite. This diversity ensures each aircraft component receives the precise type of protection and lubrication it needs to function optimally, safeguarding against potential failures that could compromise safety.

Applications and Benefits

Each type of aviation grease has its advantages that cater to specific maintenance needs, system requirements, and operational conditions. High-temperature greases, for instance, ensure continued lubrication in wheel bearings and landing gear hinge points, where heat is a constant challenge. Conversely, low-temperature greases maintain consistency in flight control systems, enabling pilots to retain maneuverability in frigid climates. The precision application of these specialized products ensures aircraft remain operational and safe for every flight.

Selecting the Right Aviation Grease

Choosing the right aviation grease isn’t as simple as grabbing the nearest tube off the shelf. Several factors come into play, such as the material compatibility with components, temperature range, and environmental considerations. For instance, when you’re selecting grease for an aircraft’s electrical system, the compatibility of the grease and the insulating materials is crucial. Engineers must also consider the frequency and ease of application as well as maintenance turnaround times to optimize lubrication practices.

Maintenance Best Practices

Aviation grease is only as good as its application. Whether it’s applied on a tight flap roller bearing assembly or a critical engine component, the correct loading and distribution of grease are paramount. Overuse can lead to excess heat buildup and unnecessary weight, which are the bane of any aircraft aiming for efficiency. On the other hand, under-allocation could result in premature wear and tear, leading to costly repairs and diminished safety margins. Accurate application based on manufacturer guidelines and an understanding of the specific operational context are the keys to effective maintenance.

The Sustainability Factor

Aviation grease ensures the sustainable operation of an aircraft’s critical systems, but its disposal can pose a hazard to the environment if not managed properly. Many jurisdictions have specific regulations for the safe disposal of grease and encourage using biodegradable or bio-based greases.

Here are some best practices to ensure you reduce your environmental footprint while staying on the right side of the law:

- Prioritize efficiency: Proper management of aviation grease presents a dual opportunity: maintaining operational efficiency and minimizing environmental impact.

- Adhere to common standards and practices: To align with environmental sustainability efforts, the industry must adhere to strict guidelines for disposing of and recycling aviation grease.

- Use modern processes: This includes categorizing waste grease as hazardous or nonhazardous based on its chemical composition and ensuring its proper disposal through specialized recycling centers or hazardous waste management facilities.

- Find sustainable alternatives: The emerging focus on bio-based greases offers a pathway to reducing reliance on petroleum products, further decreasing the ecological footprint.

- Focus on education: Aviation maintenance operations are encouraged to employ waste minimization practices such as optimizing grease application to prevent overuse and adopting closed-loop recycling systems whenever possible.

By prioritizing these sustainable practices, the aviation industry can contribute to a cleaner environment while maintaining the high standards of safety and reliability that air travel demands.

Even the Smallest Components Count

Aviation grease might not be the most glamorous aspect of the aerospace industry, but its role in the safety and efficiency of aircraft is irrefutable. By digging into the nuances of the various greases available, we can gain a deeper appreciation of the meticulous care that goes into aircraft—something we often take for granted. Understanding the different types of grease and their roles in aviation is crucial for those who fly and maintain these machines. After all, the smallest components often make the most significant contributions to the grand endeavor of flight.