Lubrication is the lifeblood of any mechanical system. Whether it’s the engine of a high-performance car or the intricate components of industrial machinery, it reduces friction, minimizes wear, and ensures optimal performance. For engineers and automotive enthusiasts alike, understanding the innovations and advancements in lubrication technology is crucial for maintaining efficiency, safety, and longevity in their respective fields.

Historical Overview of Lubrication Technology

Early Beginnings

The use of lubrication dates back to ancient civilizations. Egyptians used olive oil to reduce friction between pyramid stones, while Romans employed animal fats to grease their chariot wheels. These rudimentary methods laid the groundwork for modern lubrication technology.

Industrial Revolution

The industrial revolution marked a significant leap in lubrication technology. The advent of steam engines and complex machinery necessitated more sophisticated lubricants. Mineral oils began to replace animal and vegetable oils, offering improved temperature stability and longer service life.

20th-Century Developments

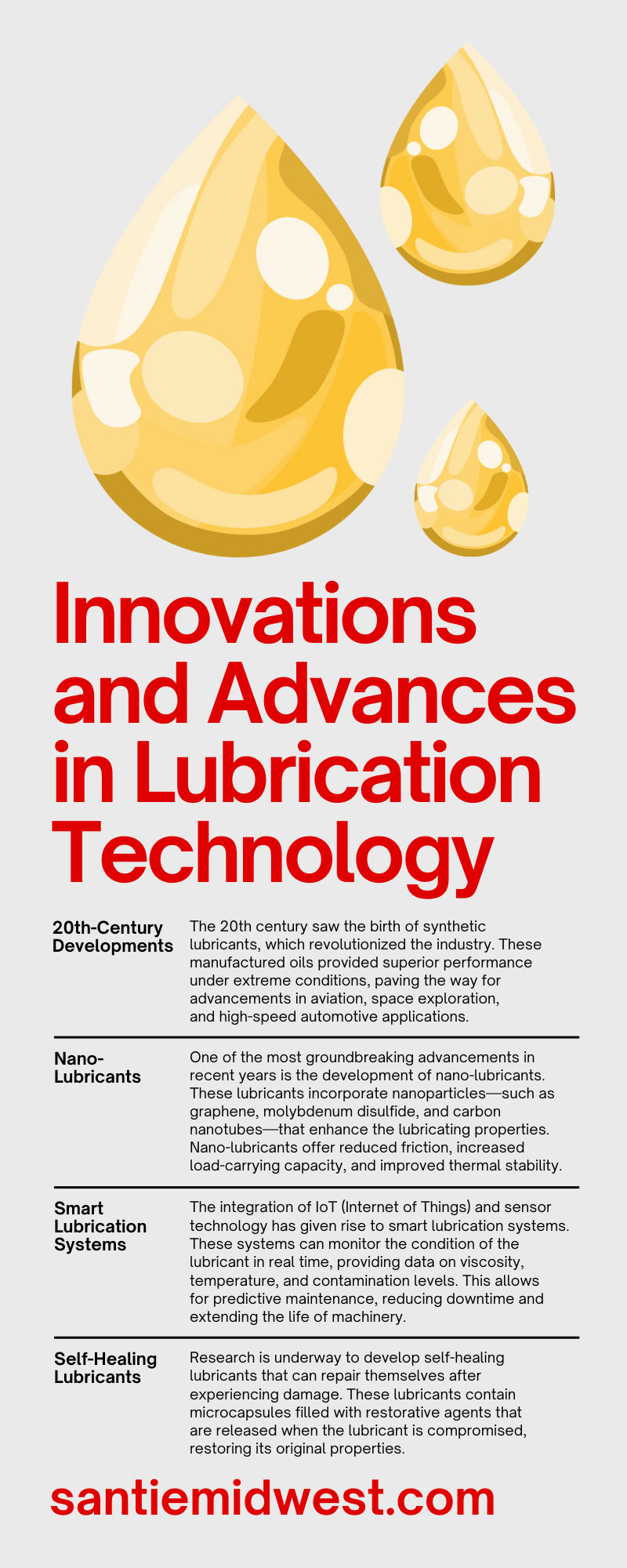

The 20th century saw the birth of synthetic lubricants, which revolutionized the industry. These manufactured oils provided superior performance under extreme conditions, paving the way for advancements in aviation, space exploration, and high-speed automotive applications.

Recent Innovations in Lubrication

Nano-Lubricants

One of the most groundbreaking advancements in recent years is the development of nano-lubricants. These lubricants incorporate nanoparticles—such as graphene, molybdenum disulfide, and carbon nanotubes—that enhance the lubricating properties. Nano-lubricants offer reduced friction, increased load-carrying capacity, and improved thermal stability.

Ionic Liquids

Ionic liquids are salts that are liquid at room temperature and possess remarkable lubricating properties. They are non-volatile, non-flammable, and offer excellent thermal and chemical stability. These properties make ionic liquids ideal for high-temperature and high-pressure applications, such as in aerospace and heavy-duty industrial machines.

Bio-Based Lubricants

With growing environmental concerns, the demand for sustainable alternatives has led to the development of bio-based lubricants. Derived from renewable sources like vegetable oils and animal fats, these lubricants offer biodegradability and lower toxicity. Innovations in this area have improved their oxidation stability and overall performance, making them viable for a wide range of applications.

Smart Lubrication Systems

The integration of IoT (Internet of Things) and sensor technology has given rise to smart lubrication systems. These systems can monitor the condition of the lubricant in real time, providing data on viscosity, temperature, and contamination levels. This allows for predictive maintenance, reducing downtime and extending the life of machinery.

Future Trends and Advances in Lubrication Technology

Self-Healing Lubricants

Research is underway to develop self-healing lubricants that can repair themselves after experiencing damage. These lubricants contain microcapsules filled with restorative agents that are released when the lubricant is compromised, restoring its original properties.

Advanced Additives

The future of lubrication also lies in the development of advanced additives that enhance the performance of base oils. These additives can provide additional protection against wear, corrosion, and oxidation and even improve the energy efficiency of mechanical systems.

The Impact of New Lubrication Technologies

Enhanced Performance and Efficiency

Innovations in lubrication technology lead to enhanced performance and efficiency in both engineering and automotive sectors. Advanced lubricants reduce friction and wear, leading to smoother operation and longer service intervals.

Environmental Benefits

The shift towards eco-friendly lubricants has significant environmental benefits. Bio-based and synthetic lubricants reduce the carbon footprint of machinery and vehicles, contributing to sustainability goals.

Cost Savings

While advanced lubricants may have a higher upfront cost, their long-term benefits include reduced maintenance costs, less downtime, and extended equipment life. This results in overall cost savings for businesses and consumers alike.

Key Industries That Rely on Lubrication Technology

Automotive Industry

The automotive industry is one of the primary sectors that rely extensively on lubrication technology. Innovations like synthetic oils and smart lubrication systems have significantly improved the efficiency, reliability, and lifespan of automotive components. Every moving part of a vehicle, from the engine to the transmission and suspension systems, requires effective lubrication to operate smoothly. High-performance engines, in particular, demand lubricants that can withstand extreme temperatures and pressures while reducing friction and preventing wear.

Manufacturing and Industrial Machinery

In the manufacturing sector, lubrication technology is critical for the proper functioning of industrial machinery. Equipment such as conveyor belts, presses, and CNC machines rely on numerous moving parts that require consistent lubrication to minimize wear, reduce downtime, and optimize productivity. Advanced lubricants with enhanced thermal stability and load-carrying capacity ensure that industrial machines can operate continuously under demanding conditions, leading to increased efficiency and cost savings.

Aerospace Industry

The aerospace industry depends heavily on state-of-the-art lubrication technology to ensure the safety and performance of aircraft. Lubricants used in this sector must perform reliably under extreme conditions, including high altitudes, varying temperatures, and significant mechanical stress. Synthetic and nano-lubricants are commonly used in jet engines, hydraulic systems, and other critical components, providing the necessary protection and reducing the risk of mechanical failures during flight.

Energy Production

Energy production facilities, such as power plants and wind farms, also rely on advanced lubrication solutions to maintain their equipment. Turbines, generators, and other energy production machinery require lubricants that can endure high loads, extreme pressure, and various environmental conditions. Effective lubrication helps to reduce operational costs, minimize downtime, and extend the life of essential equipment, thereby ensuring a steady and efficient energy supply.

Marine Industry

The marine industry, including shipping and offshore drilling operations, requires robust lubrication solutions to handle the harsh environments at sea. Marine engines, propellers, and other mechanical systems are exposed to saltwater, high pressures, and fluctuating temperatures. Specialized marine lubricants are formulated to resist corrosion, withstand extreme conditions, and provide reliable performance, ensuring the safety and efficiency of marine vessels and equipment.

Food and Beverage Industry

In the food and beverage industry, lubrication plays a critical role in the operation of processing and packaging machinery. Food-grade lubricants, which are safe for incidental contact with food products, are used to maintain hygienic standards while ensuring the smooth functioning of equipment. These lubricants must meet stringent regulatory requirements and offer properties such as resistance to water washout, oxidation stability, and non-toxicity.

By serving these diverse industries, advanced lubrication technology continues to be a cornerstone of modern engineering, ensuring the smooth operation, safety, and efficiency of countless mechanical systems worldwide.

Keep Up With This Ever-Evolving Field

The field of lubrication technology is constantly evolving, bringing forth innovations that enhance performance, efficiency, and sustainability. By staying informed and adopting these advancements, engineers and automotive enthusiasts can ensure their systems run smoothly and efficiently.

If you’re looking for the best wholesale oil distributors for your lubrication needs, look no further than Santie Oil Company. We understand the importance of quality greases and fluids, which is why we offer a wide selection of products and accessories for your manufacturing needs. Whether you’re an engineer looking to optimize machine performance or an automotive enthusiast passionate about maintaining your vehicle’s longevity, these innovations and advances in lubrication technology offer exciting possibilities for today and beyond.