If you’ve been thinking it is time to exchange your existing lubricants and oils for environmentally-friendly, green, and progressive options, you have come to the right place. Biodegradable lubricants and oils feature superior viscosity and lubricity while offering high-value flash points. Nowadays, protecting your high-value equipment and machinery through the long term is a top priority. People also prioritize contributions to the green movement taking place in many industries.

There is a certain level of confusion and stress surrounding converting equipment fluids. In this article, we help guide you through the conversion process to create a seamless transition you can trust. Converting your equipment to biodegradable lubricants is relatively simple but read on to understand best practices and techniques.

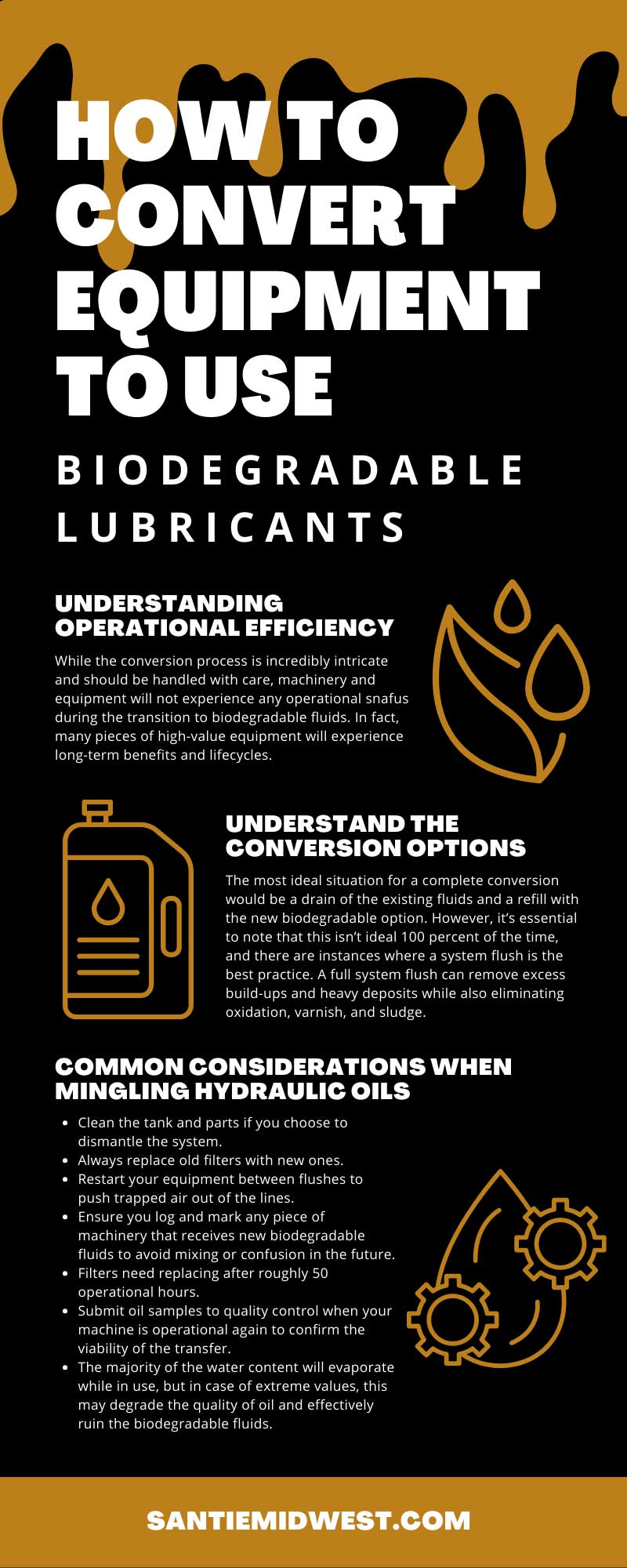

Understanding Operational Efficiency

A significant factor in converting your equipment’s fluids is understanding the operational efficiency the fluids can provide. Once users are aware of the improved lubricity, the decision to convert to biodegradable options is simple.

While the conversion process is incredibly intricate and should be handled with care, machinery and equipment will not experience any operational snafus during the transition to biodegradable fluids. In fact, many pieces of high-value equipment will experience long-term benefits and lifecycles.

Additionally, you can expect to experience operational excellence from high-quality fluids. The vast majority of biodegradable, sustainable lubricants and oils are incredibly clean and capable of withstanding normal work processes with high productivity rates.

Pre-Conversion Analysis

Before you can convert any fluids, it’s essential to give the existing fluids a thorough analysis. This will give you an indication of its condition and provide some insight into how well your machine is functioning. Some pre-conversion criteria to consider include:

- Behavior of the foaming

- Current viscosity

- Compatibility with old and new fluids

- Sampling the water content in the existing oils

If there is no available information on the existing fluids or the results are negative or inconclusive, follow the conversion details in exact detail.

Understand the Conversion Options

The most ideal situation for a complete conversion would be a drain of the existing fluids and a refill with the new biodegradable option. However, it’s essential to note that this isn’t ideal 100 percent of the time, and there are instances where a system flush is the best practice. A full system flush can remove excess build-ups and heavy deposits while also eliminating oxidation, varnish, and sludge.

The flushing system can become relatively costly when it comes to time and resources, so not many choose a complete system flush. But it’s vital to understand it may be necessary before converting. Our range of biodegradable greases and lubricants is high-quality, viable, and generally compatible with prior mineral-based systems. This means you can avoid the flushing process, drain, and refill. Partner with one of our certified industry professionals if you need help determining the best course of action for your equipment and existing fluids.

How To Execute the Process

Now that you reached a decision to convert your existing lubricants to biodegradable, sustainable options, it’s time to consider the execution process. This process is consistent whether you flushed the system or decided to drain and refill.

- It’s best to perform conversion indoors where the temperatures are optimal for viscosity rates. The interior temperature range should hover at 68 to 70 degrees Fahrenheit.

- If the hydraulic system is open, utilize a desiccant filter.

- Every manufacturer will recommend something specific to their products, so follow these guidelines for quality assurance. Each filter should retain condensation, but it’s critical to remember that water content of 1,000 or more is damaging.

- You will want to run your machinery or equipment for about 30 minutes to bring the existing oil to optimal temperature ranges.

- Open the main reservoir that houses the existing oil system and drain the fluids entirely. When the current fluids drain, replace the cartridges and filters with new ones.

- After this process, ensure the drain stops are fastened in the correct position. Refill your fluids system with your preferred biodegradable lubricant. Fill the reservoir to the appropriate fill levels and ensure all working components, lube lines, and fluid volume match the required amount necessary for performance.

- Periodically check your filters and cartridges like usual and ensure you replace anything that shows signs of impurity.

- Operate your machinery and equipment like normal.

Common Considerations When Mingling Hydraulic Oils

If you want to swap oils without dismantling all the pertinent mechanical components, draining the system entirely will still leave about 40 percent of the fluids in the cylinders, pumps, and lines. Go ahead and refill the system with new fluids and repeat the drainage procedures until the fluids begin to fill the components. You want to get the system down to two percent of old fluids to ensure a proper cleansing of the system.

Should you choose to remove parts and follow through on dismantling for conversion, you must factor in labor hours. These labor hours will help determine the best course of action regarding dismantling or not dismantling.

Some other important factors to keep in mind include:

- Clean the tank and parts if you choose to dismantle the system.

- Always replace old filters with new ones.

- Restart your equipment between flushes to push trapped air out of the lines.

- Ensure you log and mark any piece of machinery that receives new biodegradable fluids to avoid mixing or confusion in the future.

- Filters need replacing after roughly 50 operational hours.

- Submit oil samples to quality control when your machine is operational again to confirm the viability of the transfer.

- The majority of the water content will evaporate while in use, but in case of extreme values, this may degrade the quality of oil and effectively ruin the biodegradable fluids.

Santie Oil Company is your trusted source for all conversions and inventory replenishments. Connect with our trained and certified professionals to learn more about high-quality, sustainable oil options and best practices for converting your equipment. With over 40 years of industry experience and knowledge, we guarantee to keep your vital equipment and machinery operating smoothly and efficiently. Give us a call today!