Machinery operates most efficiently when components remain free from contamination and buildup. Industrial equipment faces constant exposure to oils, grease, dirt, and various contaminants during normal operations. These substances accumulate over time, creating layers that interfere with mechanical functions and reduce overall performance. Cleaners and degreasers improve machine performance by removing harmful deposits, reducing wear, and restoring equipment to optimal operating conditions.

Understanding Contamination’s Impact on Equipment

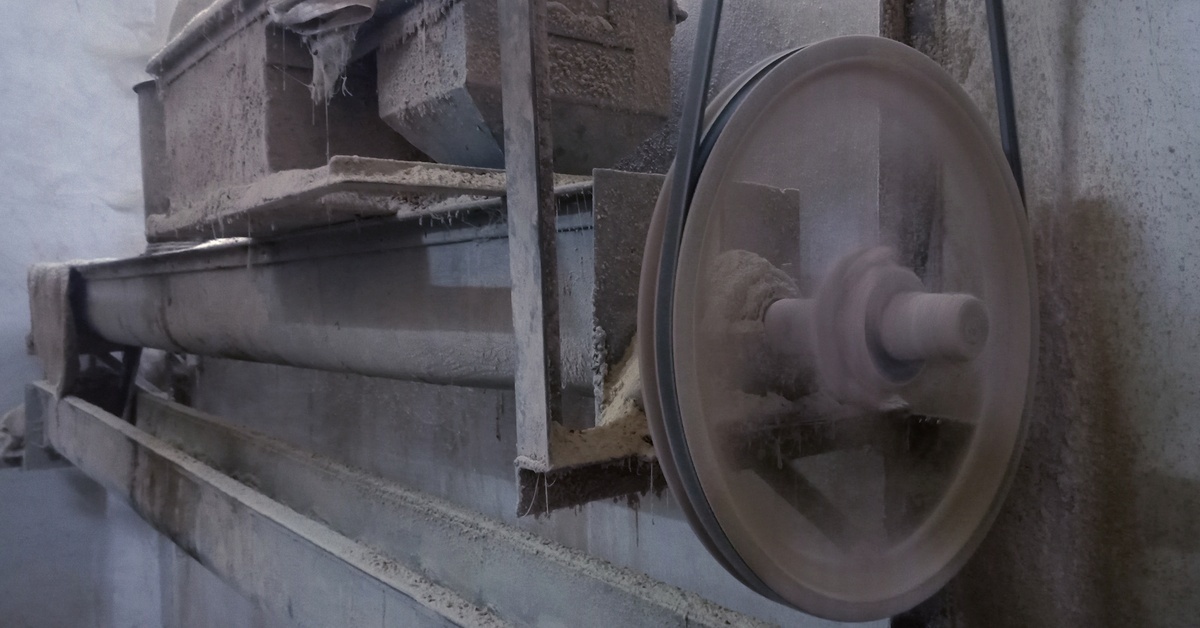

Contamination affects machinery performance through multiple mechanisms that compromise operational efficiency. Grease and oil deposits create friction between moving parts, forcing motors to work harder than necessary. Dirt particles act as abrasives, wearing down precision surfaces and creating premature component failure. These contaminants also trap heat, preventing proper thermal regulation and leading to overheating issues.

Built-up residues obstruct proper lubrication pathways, starving critical components of essential oils and greases. This lubrication deficit accelerates wear patterns and increases the likelihood of catastrophic equipment failure. Manufacturing environments particularly suffer from these issues, where production schedules depend on consistent machine reliability.

The Science Behind Professional Cleaning Solutions

Modern cleaning formulations utilize sophisticated chemical engineering principles to tackle various types of contamination effectively. Surfactants reduce surface tension between contaminants and metal surfaces, allowing cleaning agents to penetrate stubborn deposits. Solvents dissolve oil-based substances, while alkaline compounds neutralize acidic residues that cause corrosion.

Specialized degreasers employ emulsification processes that break down complex hydrocarbon chains into manageable components. These reactions occur at the molecular level, ensuring complete removal rather than simple displacement. Professional formulations balance cleaning power with material compatibility, protecting sensitive components while eliminating harmful substances.

Heat Transfer Enhancement Through Proper Cleaning

Clean equipment surfaces facilitate optimal heat transfer, which is crucial for maintaining proper operating temperatures across industrial applications. Contaminant layers act as insulators, preventing efficient thermal exchange between components and cooling systems. This thermal barrier forces cooling systems to operate beyond design specifications, increasing energy consumption significantly.

Regular cleaning with appropriate degreasers restores thermal conductivity to design specifications, improving overall system efficiency. Enhanced heat transfer reduces stress on cooling components, extending their operational lifespan considerably. Manufacturing processes requiring precise temperature control benefit from improved thermal management through professional cleaning protocols.

Reducing Friction and Mechanical Wear

Contaminated surfaces create excessive friction between moving components, accelerating wear patterns and reducing equipment lifespan. Abrasive particles embedded in grease act like grinding compounds, removing material from precision surfaces. This wear process creates play between components, reducing accuracy and increasing vibration levels.

Professional cleaning removes these harmful particles, restoring smooth operation and reducing mechanical stress throughout systems. Clean surfaces allow proper lubrication film formation, creating protective barriers between metal components. This lubrication enhancement reduces energy requirements while extending maintenance intervals and improving overall reliability.

Electrical System Performance Benefits

Electrical components suffer significant performance degradation when contaminated with oils, dust, and other conductive substances. These contaminants create unwanted electrical pathways, causing short circuits and reducing insulation effectiveness. Control panels and motor housings particularly benefit from regular cleaning with appropriate degreasing solutions.

Clean electrical connections maintain proper conductivity, reducing resistance and preventing overheating in junction boxes and terminals. Improved electrical performance translates directly into better motor efficiency and reduced energy consumption. Regular cleaning protocols prevent costly electrical failures and maintain optimal power transmission throughout industrial systems.

Preventive Maintenance Cost Reduction

Implementing regular cleaning schedules with professional cleaners and degreasers significantly reduces overall maintenance costs through extended component lifecycles. Clean equipment operates within design parameters, reducing stress on critical components and preventing premature failures. This proactive approach eliminates many emergency repair situations that disrupt production schedules.

Professional cleaning solutions penetrate areas that are difficult to reach during routine maintenance, addressing contamination before it causes damage. Early contamination removal prevents minor issues from developing into major mechanical problems requiring expensive repairs. Manufacturing facilities report substantial cost savings when implementing comprehensive cleaning protocols as part of preventive maintenance programs.

Energy Efficiency Improvements

Contaminated machinery consumes significantly more energy than properly maintained equipment, directly impacting operational costs and environmental performance. Friction from dirty components forces motors to draw additional amperage to maintain required output levels. Heat transfer inefficiencies require cooling systems to operate longer cycles, further increasing energy consumption.

Professional cleaning restores equipment to optimal efficiency levels, reducing energy requirements across all operational parameters. Clean systems require less power to achieve the same output, improving overall facility energy management. These efficiency gains compound over time, creating substantial cost savings while reducing environmental impact.

Quality Control Enhancement

Manufacturing processes depend on consistent machine performance to maintain product quality standards throughout production runs. Contaminated equipment introduces variables that affect dimensional accuracy, surface finish, and other critical quality parameters. Cleaning protocols eliminate these variables, ensuring consistent performance that meets stringent quality requirements.

Clean machinery operates within tighter tolerances, producing more consistent results and reducing waste from defective products. Quality improvement translates into higher customer satisfaction and reduced rework costs. Professional cleaning becomes an integral component of comprehensive quality management systems.

Safety Benefits Through Contamination Control

Workplace safety improves dramatically when equipment remains free from oil and grease accumulation that creates slip hazards. Clean machinery surfaces provide better visibility of potential mechanical issues, allowing operators to identify problems before accidents occur. Professional cleaning removes flammable residues that could ignite under certain operating conditions.

Proper cleaning protocols eliminate bacterial growth in cooling systems and other moisture-prone areas, improving workplace air quality. Clean equipment operates more predictably, reducing unexpected failures that could endanger personnel. Safety improvements justify cleaning investments through reduced insurance costs and improved regulatory compliance.

Implementation Best Practices

Successful cleaning programs require careful selection of appropriate cleaning agents for specific applications and contamination types. Professional assessment identifies optimal cleaning frequencies based on operating conditions, contamination rates, and equipment criticality. Training personnel in proper application techniques ensures maximum effectiveness while preventing damage to sensitive components.

Documentation of cleaning activities provides valuable data for optimizing maintenance schedules and identifying patterns in contamination accumulation. Regular evaluation of cleaning effectiveness allows for adjustments to products and procedures as operating conditions change. Professional consultation ensures cleaning programs align with manufacturer recommendations and regulatory requirements.

Measuring Performance Improvements

Quantifying cleaning program benefits requires establishing baseline measurements before implementation and tracking improvements over time consistently. Energy consumption monitoring reveals efficiency gains, while maintenance records document reduced failure rates and extended component lifecycles. Production quality metrics demonstrate consistency improvements resulting from cleaner operating conditions.

Temperature monitoring confirms improved heat transfer, while vibration analysis reveals reduced mechanical stress throughout systems. These measurements provide concrete evidence of cleaning program value, justifying continued investment in professional cleaning solutions. Regular assessment ensures programs continue delivering optimal results as equipment ages and operating conditions evolve.

Cleaners and degreasers improve heat transfer, reduce mechanical stress, and enhance overall machine performance. Regular monitoring and analysis ensure that these cleaning solutions continue to provide value as equipment conditions change over time. Investing in such programs supports long-term efficiency and reliability.