Perfluoropolyether (PFPE) grease is a high-performance lubricant with various industrial applications. With its unique chemical composition and outstanding properties, it is the go-to for engineers and technicians who demand reliability and efficiency in their machinery. If you want to get a better idea of how this lubricant operates and its benefits in various industrial applications, these frequently asked questions about perfluoropolyether grease should offer some insights.

Definition and Properties

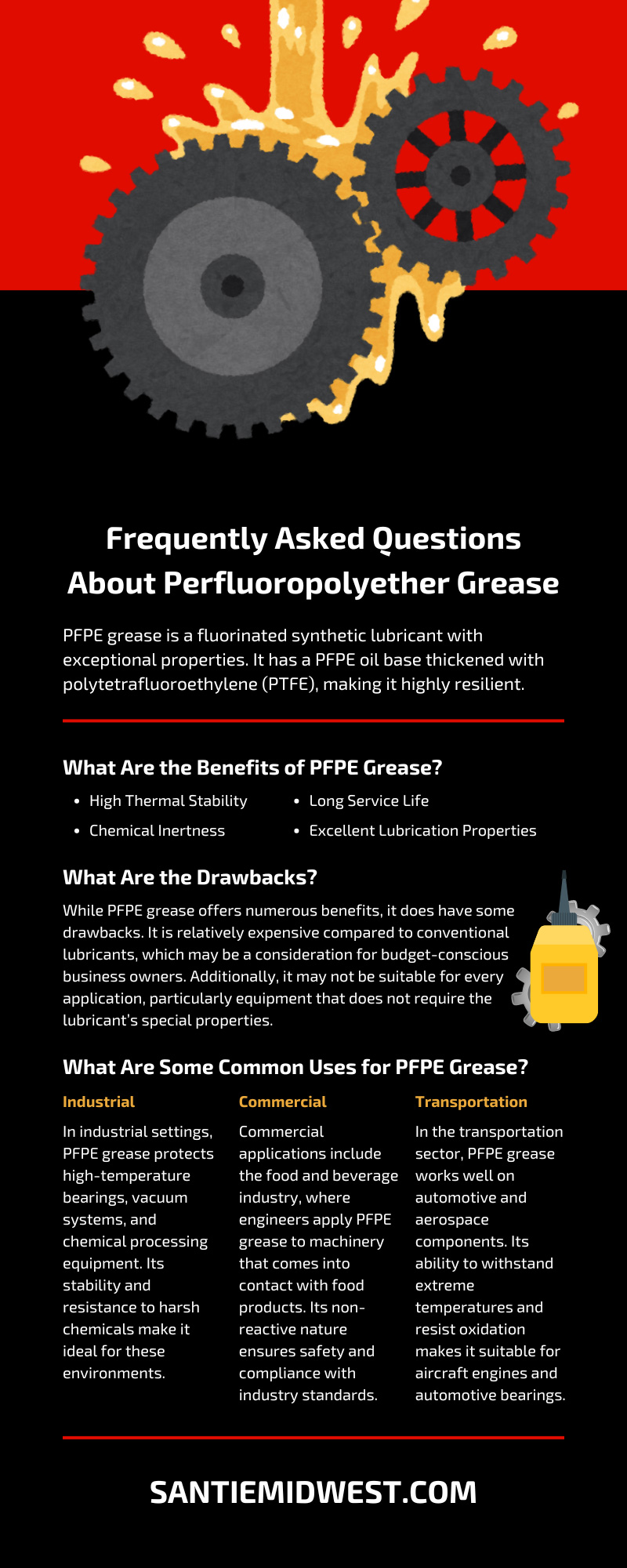

PFPE grease is a fluorinated synthetic lubricant with exceptional properties. It has a PFPE oil base thickened with polytetrafluoroethylene (PTFE), making it highly resilient.

PFPE grease has many uses across a wide variety of industries. Its versatility allows it to perform under extreme conditions, making it ideal for various commercial and industrial applications.

What Are the Benefits of PFPE Grease?

Understanding the advantages of PFPE grease can help you make informed decisions about your equipment’s lubrication needs.

High Thermal Stability

One of the standout features of PFPE grease is its high thermal stability. It can withstand temperatures ranging from -40°C to 250°C, ensuring consistent performance in freezing and scorching conditions. This stability reduces the risk of lubricant breakdown and extends the service life of your equipment.

Chemical Inertness

PFPE grease is chemically inert, meaning it does not react with most chemicals, solvents, or gases. It’s perfect for use in environments where exposure to aggressive substances is common. It also ensures that the grease does not degrade or compromise the materials it comes into contact with.

Long Service Life

The long service life of PFPE grease is another significant benefit. Due to its stability and resistance to oxidation, it requires less frequent reapplication compared to other lubricants. Longevity translates to reduced maintenance costs and downtime, as well as better operational efficiency.

Excellent Lubrication Properties

PFPE grease provides superior lubrication to reduce friction and wear on moving parts. Its ability to maintain consistency under varying conditions supports smooth operation and minimizes the risk of component failure. It’s an invaluable asset in maintaining your machinery.

What Are the Drawbacks?

While PFPE grease offers numerous benefits, it does have some drawbacks. It is relatively expensive compared to conventional lubricants, which may be a consideration for budget-conscious business owners. Additionally, it may not be suitable for every application, particularly equipment that does not require the lubricant’s special properties.

What Are Some Common Uses for PFPE Grease?

PFPE grease is versatile and has applications across various sectors. Knowing how to leverage its properties allows business leaders to improve their bottom line and reduce waste.

Industrial

In industrial settings, PFPE grease protects high-temperature bearings, vacuum systems, and chemical processing equipment. Its stability and resistance to harsh chemicals make it ideal for these environments.

Commercial

Commercial applications include the food and beverage industry, where engineers apply PFPE grease to machinery that comes into contact with food products. Its non-reactive nature ensures safety and compliance with industry standards.

Transportation

In the transportation sector, PFPE grease works well on automotive and aerospace components. Its ability to withstand extreme temperatures and resist oxidation makes it suitable for aircraft engines and automotive bearings.

What Are Best Practices for Cleanup and Maintenance?

Cleanup and storage of PFPE grease are essential to maximize its effectiveness and ensure the longevity of your equipment. When dealing with PFPE grease, it’s important to follow these basic guidelines.

Safe Removal of PFPE Grease

Removing PFPE grease from machinery and components requires the use of appropriate solvents. Fluorinated solvents are best due to their compatibility with PFPE grease. Follow manufacturer guidelines and safety instructions when selecting and using solvents in order to prevent damage to equipment and ensure personal safety.

Reapplication Best Practices

Regular reapplication of PFPE grease enhances the performance and extends the life of your machinery. Before reapplying, remove the used grease to avoid contamination. Apply a thin, even layer of new grease following the manufacturer’s recommendations for temperature and pressure specifications.

Care and Handling of PFPE Grease

Proper care and handling of PFPE grease ensure its efficacy and protect both the product and the people handling it. Store PFPE grease in a cool, dry place where it won’t be exposed to direct sunlight or extreme temperatures. Ideal storage temperatures range from 10°C to 30°C. Always keep the grease in its original, sealed container to prevent contamination and moisture ingress.

How To Dispose of PFPE Grease?

Proper disposal of PFPE grease is crucial for both environmental safety and compliance with regulatory standards. Here are key considerations for disposing of PFPE grease:

1. Identifying PFPE Grease Waste

- Separate used PFPE grease from other waste materials to avoid cross-contamination, and label containers clearly to ensure correct disposal.

- Evaluate whether the PFPE grease can be recycled, repurposed, or disposed of completely.

2. Regulatory Compliance

- Familiarize yourself with local environmental regulations concerning industrial lubricant disposal. Regulations may vary, so follow the rules applicable to your region.

- Keep records of disposal activities, including quantities and types of PFPE grease disposed of and the methods you used. This documentation may be necessary for regulatory compliance and audits.

3. Disposal Methods

- Dispose of PFPE grease through authorized waste disposal services that specialize in handling industrial lubricants, as they can manage hazardous materials safely.

- Participate in recycling programs if available. Some facilities may be able to reclaim and recycle the PFPE oils.

4. Handling and Transporting Waste

- Use sealed, leak-proof containers when transporting used PFPE grease to disposal or recycling facilities. Clearly label all containers to prevent mishandling.

- Ensure that personnel involved in handling and transporting waste PFPE grease have suitable personal protective equipment (PPE) to reduce exposure risks.

5. Environmental Impact

- Never dispose of PFPE grease in regular trash bins, down drains, or near bodies of water. Improper disposal can lead to soil and water contamination and harm surrounding ecosystems.

- Adopt sustainable disposal practices, such as using environmentally friendly solvents and participating in initiatives that reduce industrial waste.

By adhering to these disposal protocols for PFPE grease, you contribute to environmental protection and ensure compliance with industrial standards. Additionally, you maintain the safety and integrity of your workplace and the broader community.

Keep Your Equipment Lubricated and Running Efficiently

PFPE grease is a high-performance lubricant that offers numerous benefits for industrial applications. Its thermal stability, chemical inertness, and long service life make it valuable for engineers and technicians. By understanding its properties and applications, you can make informed decisions about its use in your operations.

These frequently asked questions about perfluoropolyether grease should offer some insights into how you can leverage it for success. If you’re looking for quality lubricants, such as Castrol aviation oil, Santie Oil Company has what you need. We’re here to answer any questions you might have so you can keep your equipment running.