Knowing how frequently to change your diesel engine oil is essential for optimal performance and engine longevity. Diesel engines are heavy-duty powerhouses designed to handle tough tasks, so they require meticulous maintenance to run at their best.

Consider a commercial truck that operates over long distances daily. These vehicles typically require oil changes every 25,000 to 50,000 miles, depending on the type of oil and driving conditions. A local delivery van with a diesel engine, however, may have shorter oil change intervals due to frequent stops and starts.

Unlike gasoline engines, diesel engines require a different approach to oil changes due to their distinct operating conditions and components. Read on to learn about best practices and the ideal frequency for changing diesel engine oil.

Why Diesel Engines Need Timely Oil Changes

Diesel engines operate at high temperatures and pressures, which cause the oil to oxidize quickly. Poor lubrication caused by oxidized oil can damage engine components, such as pistons and crankshafts. It’s best to use high-quality oils that can handle these extreme conditions.

For instance, a marine diesel engine tasked with powering fishing boats might need synthetic oil due to its long life and ability to resist breakdown at high temperatures.

The Role of Engine Type in Oil Change Frequency

The type of diesel engine you have affects oil change intervals. Light-duty engines in consumer vehicles can adhere to manufacturer specifications of 5,000–7,000 miles per change. Heavy-duty engines in construction equipment endure harsher conditions and require less frequent but thorough maintenance.

A light-duty diesel SUV used mainly for highway commuting could rely on conventional oil and stay near the upper end of the recommended oil change interval. Conversely, a diesel bulldozer working on construction sites might require regular oil analysis to monitor the condition of its lubricant, ensure optimal performance and prevent issues.

Understanding Oil Quality and Its Impact

When changing diesel engine oils, the quality of the oil matters as much as how often you change it. Diesel engines operate under high pressure and heat, making it critical to use oil that can withstand these conditions. Engineers design high-quality synthetic oils to resist thermal breakdown, maintain viscosity under stress, and minimize the formation of harmful deposits. These features protect engine components, enhance fuel efficiency, and extend engine life.

While conventional oils may offer short-term savings, they break down quickly, allowing for more sludge and carbon buildup and increased engine wear. Investing in premium oil may be a higher upfront cost, but it pays off in performance and durability.

Suppose a fleet manager at a long-haul trucking company were to switch to a premium synthetic diesel engine oil. In that case, they might be able to extend oil change intervals to 20,000–40,000 miles. This increase could enhance engine cleanliness and performance while reducing maintenance costs and downtime.

Signs That Diesel Engine Oil Needs Changing

Sometimes, external cues can signal the need for an oil change sooner than expected. Dark, dirty oil, a noticeable decrease in engine performance, or an illuminated oil warning light are all indications of a problem. Regular monitoring can prevent engine deterioration.

Take, for example, a logistics firm noticing a drop in fuel efficiency in their diesel trucks. An inspection might reveal that overdue oil changes degraded engine performance. Updating the oil maintenance schedule could resolve the issue.

The Impact of Driving Conditions

Driving conditions affect the longevity of diesel oil. Trucks on long highway hauls experience less stress on engine oil compared to off-road vehicles operating in dusty or rugged environments. Extreme heat, cold, or heavy towing loads also accelerate oil degradation.

Consider a farmer operating a diesel-powered tractor to plow fields in the summer. They may observe that the tractor’s oil was breaking down more quickly than anticipated. By switching to a specialized oil formulated for extreme temperatures, they avoided further complications.

Manufacturer Recommendations and Maintenance Logs

Sticking to your vehicle manufacturer’s recommendations is key. Manufacturers tailor these oils to the engine type in your vehicle. Pairing recommendations with a strict maintenance log ensures you never miss an oil change, helping to extend your engine’s life.

Imagine a diesel pickup truck owner who discovers they’ve been changing the oil too frequently. After carefully reviewing the owner’s manual, they adjust the oil change schedule, saving money while maintaining optimal performance.

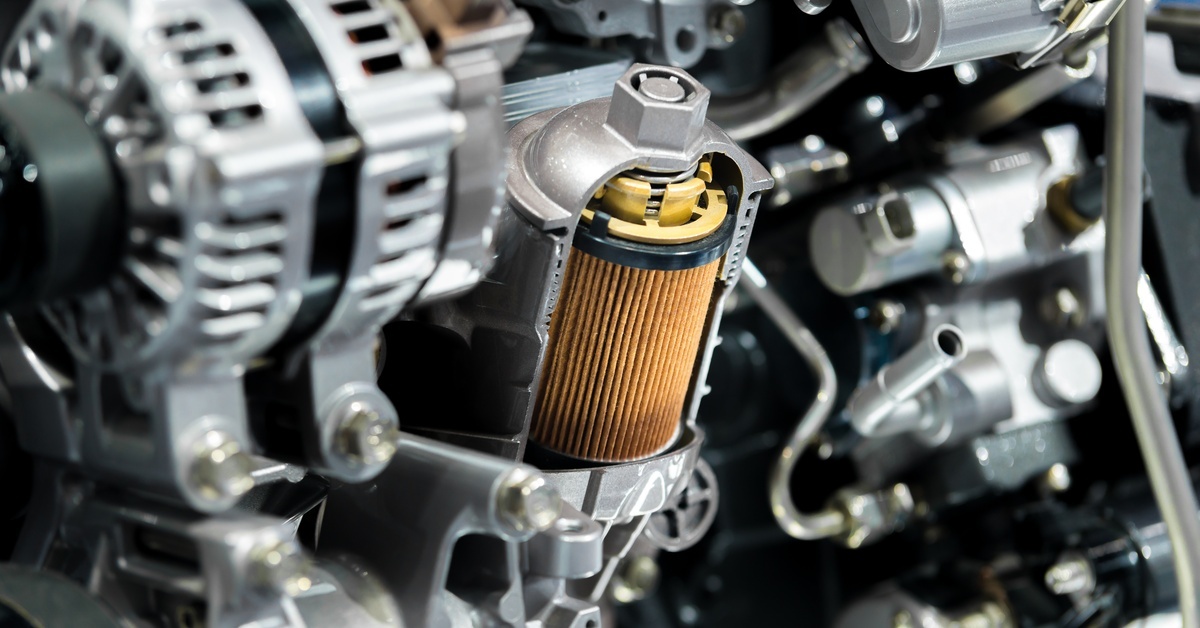

The Importance of Oil Filters

A new filter is just as important as new oil. A clogged or dirty oil filter can restrict oil flow and reduce its effectiveness, allowing contaminants to circulate and cause internal wear. Replacing the oil filter with every oil change is essential for maintaining engine health, maximizing performance, and preventing problems.

Imagine a transport company facing frequent engine failures in its diesel fleet. Investigating the problem, they discover that their maintenance team has been skipping oil filter replacements. Severely clogged filters can restrict oil flow, causing overheating and premature engine wear. By enforcing a strict policy to replace filters during every oil change, the company can reduce breakdowns and service disruptions, improve fleet reliability, and achieve long-term savings.

Benefits of Regular Diesel Oil Maintenance

Regular oil changes enhance engine efficiency, lower emissions, prevent engine degradation, and help you save money. For example, a freight company can reduce operational downtime by 30 percent by adopting a stricter diesel engine oil maintenance schedule. The maintenance team can keep trucks running cleaner and deal with fewer engine faults.

DIY vs. Professional Service

While many drivers prefer professional services for oil changes, some choose the DIY route to save costs. If you opt for a DIY approach, ensure you have the right tools, follow the manufacturer’s guidelines, and dispose of used oil responsibly.

If you are part of a trucking company and implement real-time oil monitoring across its fleet, you eliminate unnecessary oil changes and stay ahead with proactive maintenance.

Future Trends in Diesel Engine Oil Technology

Advancements in diesel engine oil technology could extend oil life and enhance performance. Oil analysis kits and real-time monitoring sensors enable drivers to make informed decisions about oil changes. Imagine a trucking company implementing real-time oil monitoring across its fleet. This system helps them avoid unnecessary oil changes and enables proactive maintenance.

Wrapping Up Diesel Engine Oil Best Practices

Maintaining the health of diesel engine oil is essential for maximizing performance, minimizing costs, and extending the life of your engine. Pay attention to your driving conditions, use high-quality oil, adhere to manufacturer guidelines, and never skip oil filter replacements. By following these best practices for changing diesel oil, you can ensure your diesel engine stays in top condition.