When it comes to finding the right industrial lubricant for your application, there’s a lot to consider, and it can make even a seasoned pro’s head spin. If you’re struggling to find the right lubricant for your business or are intimidated by the prospect of buying wholesale lubricants, you’re not alone. That’s why we’ve compiled the ultimate guide to buying oil, lubricants, and grease in bulk.

What Do You Need Lubricant For?

Your application will help you answer almost every question in this buying guide, so your first job is to identify what your lubrication needs are. Every application, whether it be automotive, aerospace, aviation, or military, requires different lubricants to meet different needs. Of course, all lubricants help parts move, but the type of environment the formulation has to remain stabilized in makes formulations and viscosities vary widely.

For example, engine oils in fleet vehicles have to withstand a lot more pressure and heat than those in regular vehicles. Lubricants for the nacelles of wind turbines must be able to withstand the cold and therefore need more viscosity stabilizers. The more precise of an application idea you have, the easier it is to buy exactly what you need.

What Kind of Lubricants Do You Need?

If we break it down into its simplest terms, there are two types of lubricants: grease and oil. Although people often use these terms interchangeably, their formulations and applications are very different. Oil exists in a much more liquid form than grease does, as it has different ratios of base oil and thickener additives. Why does this matter?

Think of it this way—you wouldn’t expect a colander to hold vegetable oil, would you? Let’s look at a more applicable example. Wind turbines need grease and oil to function. This is because there are open-gear systems and closed-gear systems known as gearboxes. If you were to use regular, low-viscosity oil on an open gear system, leaks would occur unless you siphoned it through a distribution system, which not all parts have. Conversely, if you filled an engine with grease instead of engine oil, the parts would struggle to move, and the engine would very quickly overheat.

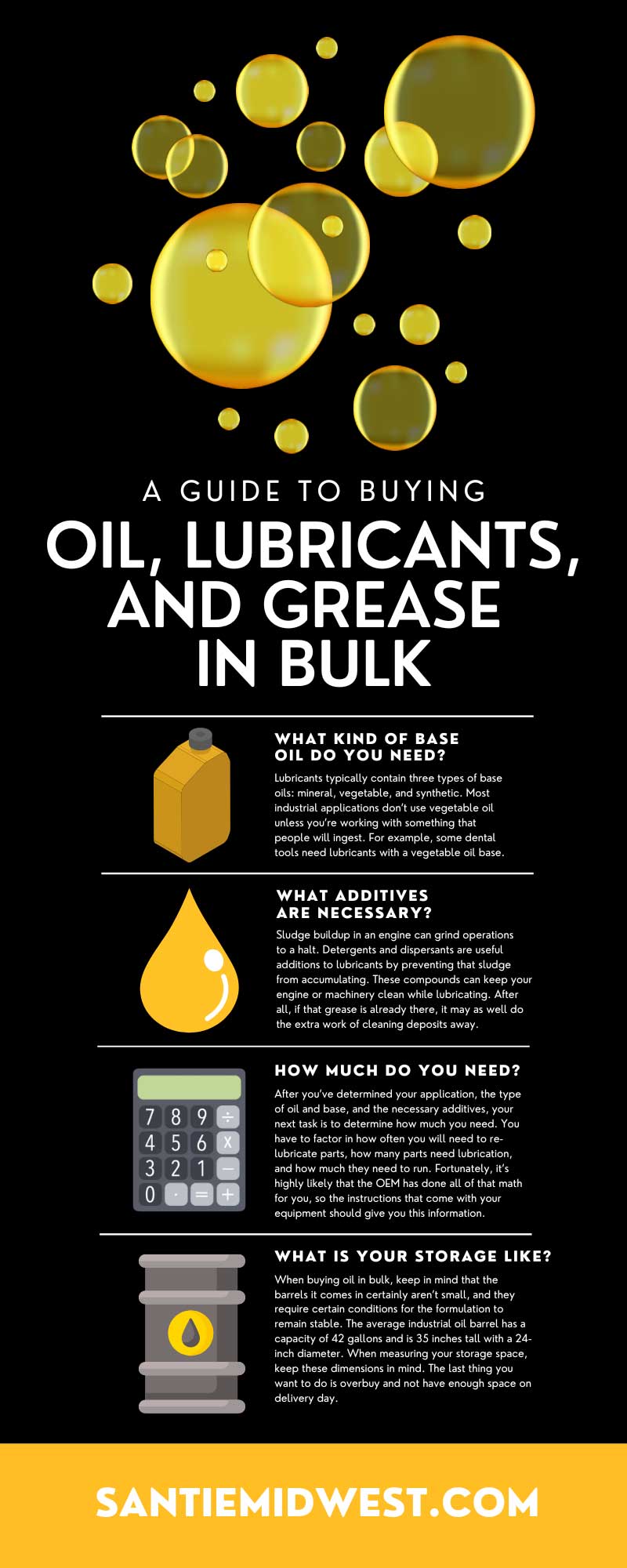

What Kind of Base Oil Do You Need?

Lubricants typically contain three types of base oils: mineral, vegetable, and synthetic. Most industrial applications don’t use vegetable oil unless you’re working with something that people will ingest. For example, some dental tools need lubricants with a vegetable oil base.

Mineral oils are straight crude oil and are very thin and not as durable as synthetic or partially synthetic oils. This is because synthetic oils have additives that allow them to exist in settings with high environmental demands, all while protecting equipment. For example, if you work in an off-shore industry, your machinery is likely going to experience a lot of salt spray and humidity. In this case, you’d need synthetic oil, as it has the necessary corrosion and dispersant additives. However, because fully synthetic oil is expensive, many industries prefer to use semi-synthetic oil cut with mineral oil, so be sure to keep that in mind when determining your budget.

What Additives Are Necessary?

Lubricants are incredibly useful. However, with high-pressure situations and shifting elements, pure base oils can’t do it alone. Your lubricant, no matter its application, can benefit from select additives that will bolster its efficacy in a variety of applications without compromising its primary function—to keep things moving.

Sludge buildup in an engine can grind operations to a halt. Detergents and dispersants are useful additions to lubricants by preventing that sludge from accumulating. These compounds can keep your engine or machinery clean while lubricating. After all, if that grease is already there, it may as well do the extra work of cleaning deposits away.

Sometimes, you need an additive to counteract another additive. For example, antifoaming agents appear in lubricants that also contain added detergents. Detergents and surfactants can cause foaming, which could inhibit your lubricant’s primary function. These agents prevent foam from developing from that friction while still letting the detergent do its dirty work.

In settings where heavy moisture can be a factor, corrosion inhibitors prevent metal surfaces from rusting or corroding. They do this by staving off rust from iron and steel or blocking the corrosion of non-ferrous metals and alloys.

And with high humidity often come wild variations in temperature. That’s where viscosity modifiers come in. These additives are the Goldilocks of your arsenal—they help maintain your lubricant’s viscosity through extreme heat and cold, preventing it from ever becoming too thin or too thick. Whatever your operating temperature may be, a viscosity modifier keeps things just right.

How Much Do You Need?

After you’ve determined your application, the type of oil and base, and the necessary additives, your next task is to determine how much you need. You have to factor in how often you will need to re-lubricate parts, how many parts need lubrication, and how much they need to run. Fortunately, it’s highly likely that the OEM has done all of that math for you, so the instructions that come with your equipment should give you this information.

However, you may still have to do a little bit of calculating. You may have multiple of the same machine or a wide variety of machinery that needs lubrication, so you’ll have to consider this when deciding how much to buy. Once you know how much you need, then you can start planning for the future. It’s not efficient or financially viable to buy lubrication every time you need it. So when determining your budget, consider purchasing extra barrels to prevent panic when you run low.

What Is Your Storage Like?

When buying oil in bulk, keep in mind that the barrels it comes in certainly aren’t small, and they require certain conditions for the formulation to remain stable. The average industrial oil barrel has a capacity of 42 gallons and is 35 inches tall with a 24-inch diameter. When measuring your storage space, keep these dimensions in mind. The last thing you want to do is overbuy and not have enough space on delivery day.

Additionally, it’s important to keep all your lubricants in a dry, clean, and cool environment in adequate shelter. Ideally, you’ll have plenty of indoor storage space to keep your lubricants in optimal condition. If not, make sure you protect your containers from the elements and lay them on their side to reduce moisture intake.

Hopefully, this tip guide to buying oil, lubricants, and grease in bulk helps make the purchasing process a little easier. If you have any more questions, contact Santie Oil today. We’re an industrial oil distributor dedicated to being your one-stop shop for all of your lubrication needs.